Are you struggling to choose the right drill bit size for the pilot drill? Don’t worry you have come to the right place because, in this blog, I’m going to show you how you can choose the right drill bit size for your project.

There are three ways you can choose the right drill bit size for pre-drill; first, I will show you a mediocre way, and then I will show you two better ways.

1. Hit & trial method to choose the drill bit size

This method is not an exact way to choose the right drill bit size, but it can give you a pretty good idea of which drill bit size fits your screw.

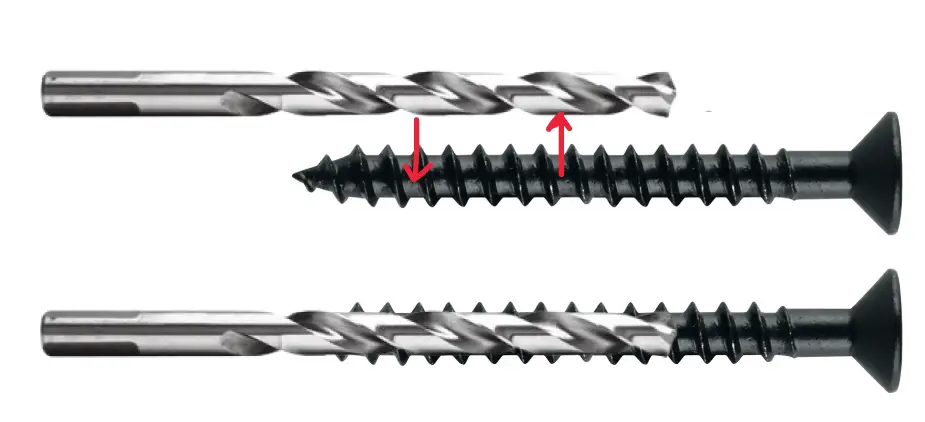

First, take a drill bit roughly of the same size as the screw. Hold the drill bit in front of the screw in this way, and you should be able see a good amount of threads of the screw, as shown in the picture below. In this way, the threads could catch inside the drilled hole.

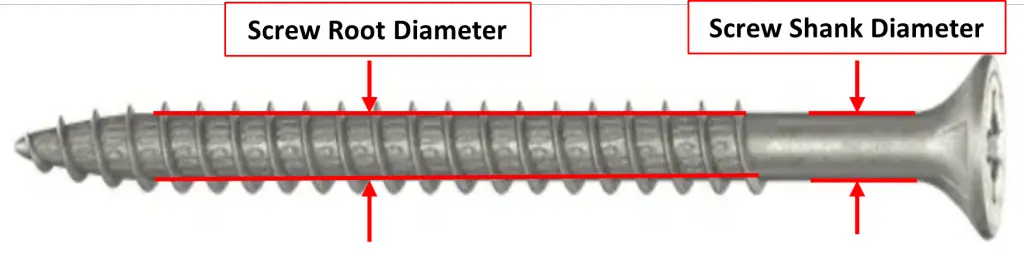

In other words, the Root/Shank diameter (please see the above picture) of the screw and drill bit should be roughly the same size.

Please Note that the Root diameter is always smaller or equal to the Shank diameter. Make sure you compare the screw root diameter with the drill bit. This method is limited to woodworking.

2. Measuring the Screw Shank Diameter

This method requires a measuring instrument like a vernier caliper, screw gauge, or even scale. First, measure the diameter of the screw and then measure the diameter of the drill bit with the help of an instrument. The diameter of the drill bit should be a fraction less than the shank diameter of the screw.

Let’s say I have measured the shank diameter of the screw to be 0.127 inches; then I will measure the drill bit size by instrument I would pick the drill bit size closer to the shank diameter. Say I have measured two drill bits one reading is 0.114 inches & other is 0.124 inches I would pick 0.124 inches drill bit for the pre-drill.

3. By using Sizing Chart

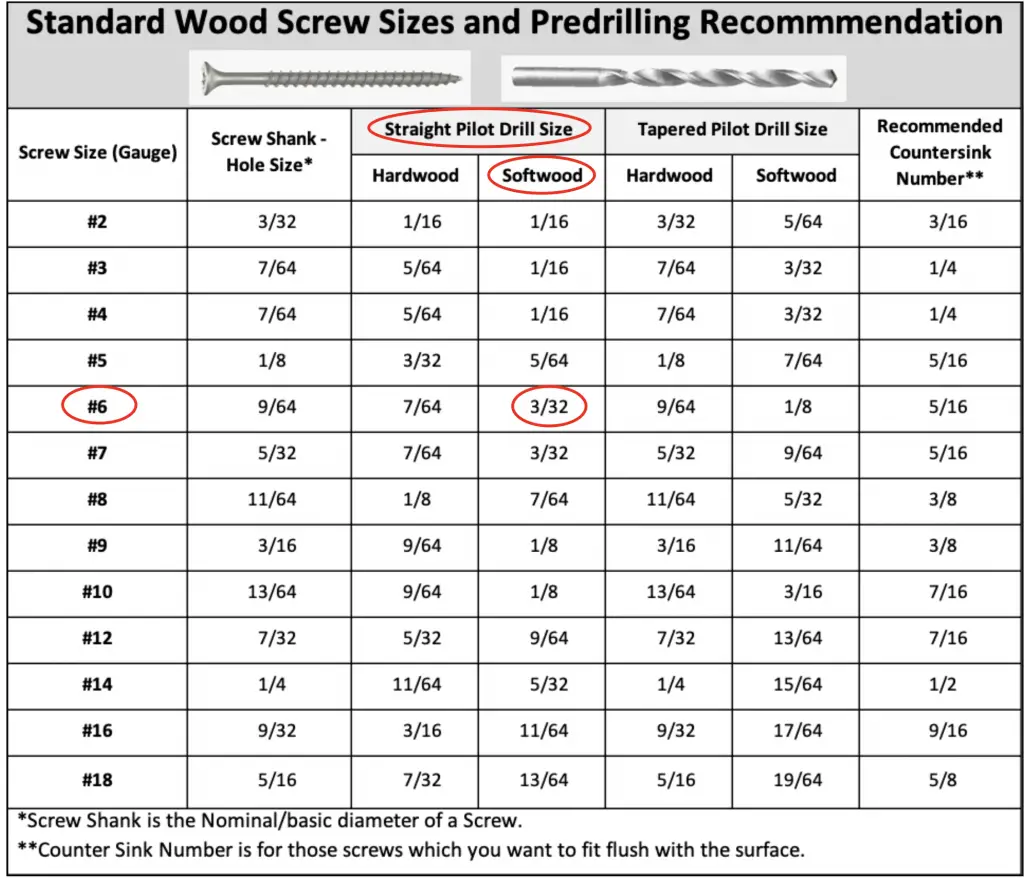

This method is very efficient when you are working daily on a project. Multiple charts are available online, which are a bit complicated to understand.

In this blog, I have shown different charts for wood, metal & concrete pre-drill/pilot holes. Once you understand these charts, you can easily read any drill bit size chart for pre-drilling on any surface.

3.1 Drill bit size Chart for Wood Working

Here’s how you can navigate through the standard wood screw chart. Let’s say I want to drill a number 6 size screw into a softwood.

First, I’ll look for screw size, which is #6 in our case, then I’ll come down the chart through the same column and look for straight pilot drill size and softwood. You will be able to identify a value of 3/32.

This value of 3/32 is the drill bit size you should use.

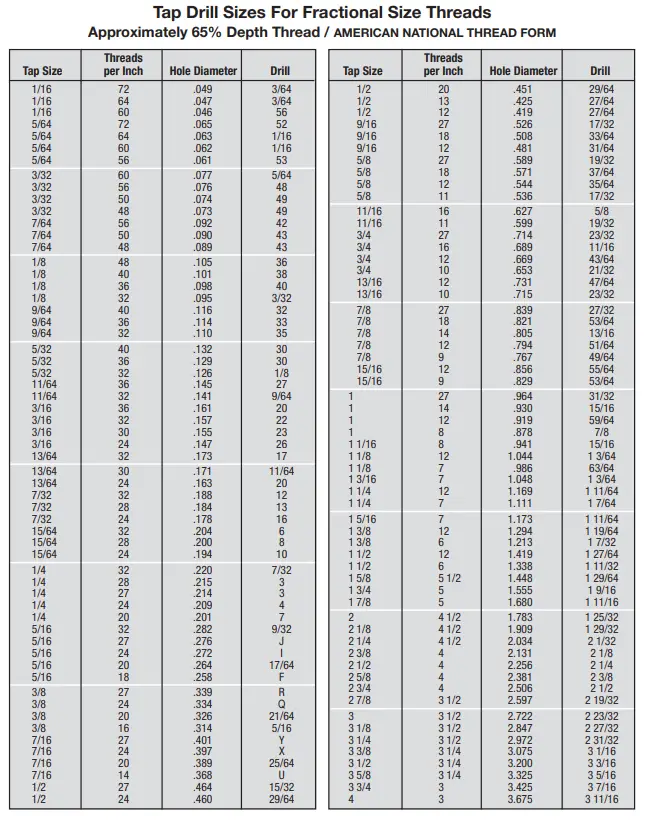

3.2 Drill bit size Chart for Metal Working

There are two types of screws for metals. One is called a self-drilling screw, whose size is the same as the screw you’re going to install & other is called a self-tapping screw.

Self-drilling screws don’t need a pilot hole. They can drill their hole when you’re driving them in.

Self-drilling screws have different schedules for different thickness surfaces. You can find different online sources to select your screw per your requirement.

Want to know which drill bit is best for your metal work? You can check it out here.

Following are some websites you can check.

- https://www.grabberpro.com/userfiles/documents/TechnicalDocuments/Manuals/Self-Drilling-Screw-Selection-Guide.pdf

- https://www.teksscrews.com/support/full-line-catalog/

- https://fabral.com/wp-content/uploads/2021/11/fab_98-32-110_fasteningschedule_1-20-17_pages-web.pdf

- https://www.tannerbolt.com/media/pdf/catalogs/Self-Drilling%20Screws.pdf

But a self-tapping screw mostly needs a pilot hole if the metal is too hard or thick. Then you’ll need to drill a pilot hole using a drill in rear cases. There is no need for a pilot hole if the metal is too soft or thin.

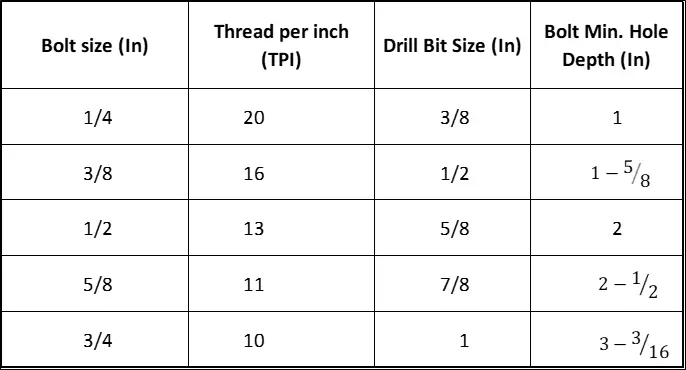

Drill bit size can be selected from the following table. (Tap size will become your screw size, based on this, you can select the drill bit size).

3.3 Drill bit size chart for Masonry Material Working

Masonry materials include Reinforced concrete, Cracked Concrete, Granit, Stone, Rock, Cellular Concrete, Breeze Block, Hollow Brick, Plaster, Tile, etc.

Drilling through masonry material is a complicated job & requires the proper selection of drill bit material. Once you select the suitable drill bit material, you can use the following table to select the correct bit size.

You can check multiple other online sources to determine the correct drill bit size for numerous sizes.

How Deep Should the Pilot Hole be & when to stop Drilling?

The depth of the pilot hole depends on the surface you’re drilling. For soft surface workpieces like softwood (Pine, Cedar, Larch, Redwood, Douglas fir, etc.), the pilot hole should be a little less than the length of the screw you will install. The reason being the oft surface can compress upon screw pressure.

For hard surface workpieces like hardwood (Alder, Ash, Oak, Walnut, Willow, etc.), metal and the concrete pilot hole should be a little larger or even to the length of the screw.

Hard surfaces cannot bear the high pressure from the screw. If the pilot hole is not long enough deep, the screw can damage the surface resulting in poor strength and quality.

To drill the correct pilot hole depth, the following steps to be followed:

Step 1) Take tape or marker.

Step 2) Take the screw & drill bit. Compare the screw with the drill bit starting from the drill bit’s tip. Marked or taped the length on the drill bit according to the surface; if the surface is soft, mark the point a bit less on the drill bit than the screw length if the surface is hard, mark the point a bit greater on the drill bit than the screw of length.

Step 3) Start drilling with the marked drill bit, and retreat when you reach the marked point.

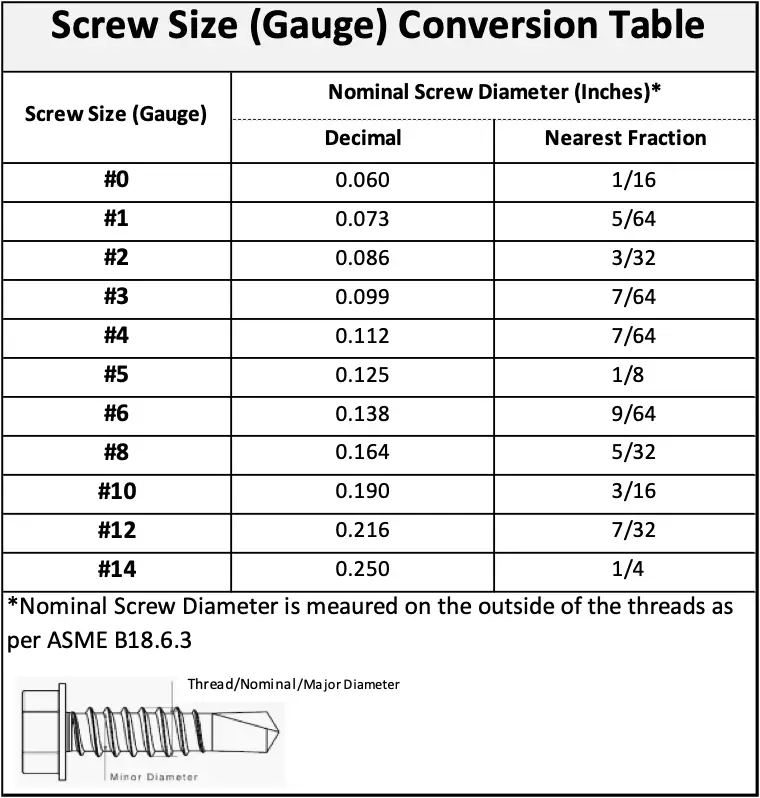

What does the Screw size (Gauge) mean, and How do you know which Screw size (Gauge) you are using?

Screw size (Gauge) is simply the Thread/Major/Nominal diameter of the screw. In the Imperial System, when the primary diameter of a screw is less than ¼ inches, it is represented by a gauge number, starting from #0 for fine-thread screws, while for coarse-thread screws, it starts from #1.

Using the conversion table above, you can convert any screw size (gauge) into the nearest fraction.