Determining the exact screw thread size is handy when you are out there trying to find the correct parts to continue doing your project without any hassle, and to be honest, it isn’t much of a big deal.

It seems like a lot of hard work, but trust me, a little knowledge and understanding of mathematics can simplify many things. Here is how you can measure a screw thread size;

Primarily, you can measure a thread size using the imperial, metric, or thread gauge. These systems depend on the threads you are using, as some will have their measurement listings.

All you need for the imperial and metric system is a measuring tape and some screws in hand. You can measure the length and the diameter of the screws first and begin with the threads counts.

Diameters of Screws

For measurements of the diameter, You will first need to identify the major diameter, that is, to measure the space from the external thread of one side to the other.

The major diameter is mainly the actual size of the screws or bolts. Then comes the minor diameter, which you can measure from the bottom cavity of the thread of one side to the other.

Length of Screws

The length of screws is the distance that starts from the flat part at the top to the end of the screw. You are most likely to come across screws with a flat part either at the top or the bottom.

When you want to measure the length of the screws that have a flat top, like the flat head or the countersunk screws, you will have to measure from the flat top of the screw to the end tip.

Other screws that have a flat part at the bottom, like the pan heads, truss heads, or round heads, need to be measured from the bottom flat part to the end tip of the screw.

You can use the same technique to measure the length of the screws that have a flat top as well as a flat bottom part. These include the hex and hex washer head screws.

For the oval head screws, it is best to take the widest part of the head as your starting point and go up to the tip of the screw.

If you are stuck with a stripped screw, refer to my blog on How to remove a stripped screw.

How to Measure Screws with Imperial System?

The imperial measuring system measures screw thread size with respect to the inches, also known as TPI (threads per inch). In this method, you will have to sum the thread peaks of a screw across the 1-inch length.

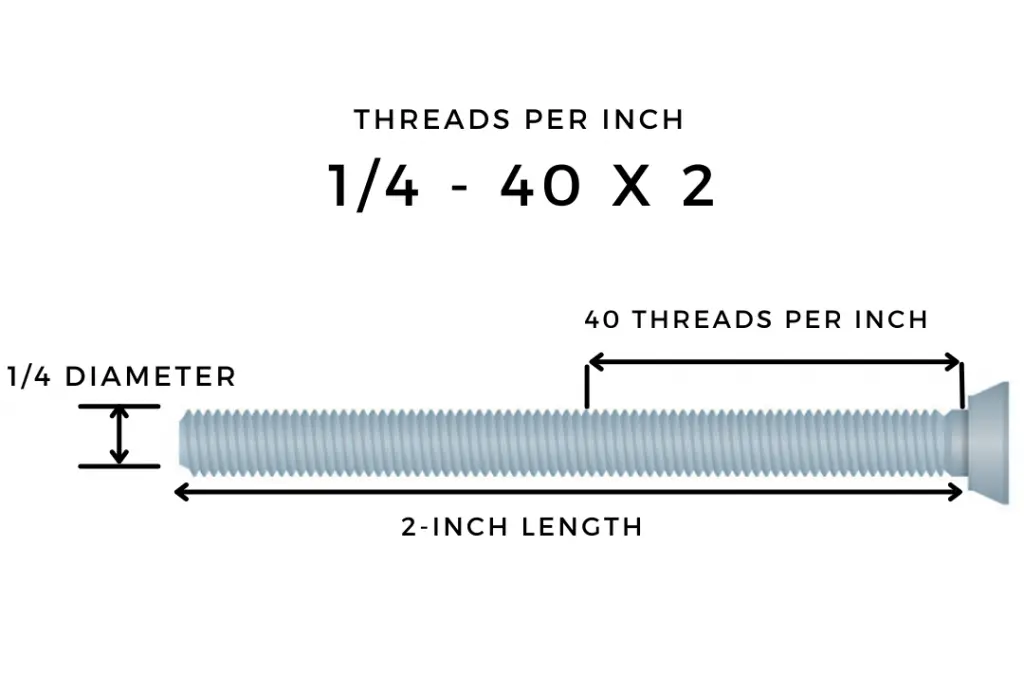

When determining a fixed size, you should remember that the TPI measurement has a common form of imperial thread size that we use often. For instance, a 1/4-20 sized thread would indicate a 1/4 inch diameter and 20 thread per inch.

The process of the measurement is simple. All you need to do is to put the screw on a flat surface and let its head hang off in a way that the threads seem flat.

Then, grab a measuring rule or a tape, put it through the axis of the screw, and measure the length as I have mentioned above.

For counting the threads, make sure to count the first thread of the screw as zero instead of one, as it will make the results come as precise as possible.

You will have to keep the screw flat for the diameter and use a measuring tape or a rule and measure from one side to the other while using the nearest fraction of an inch.

There is a gauge number/fraction in an inch for the imperial system with which we denote the diameter. In order to find the gauge number, you will have to refer to the gauge guide, which is also available online.

Now that you have a length, diameter, and TPI, you can easily represent the size of the screw thread. For instance, ‘1/4 – 10 x 2’ shows that the screw has a 1/4 diameter, 10 TPI, and a length of 2-inch.

How to Measure Screws with Metric System?

Unlike the imperial system, the metric system uses thread pitch to identify the size of a screw thread. The first step is pretty much similar to the previous system in which you have to calculate the length of the screw thread using a measuring tape or a rule.

The only difference is that you will take values in millimeters rather than inches this time. After the length, measure the diameter of the screw thread in millimeters by placing a ruler and start counting the adjacent sides of the screw,

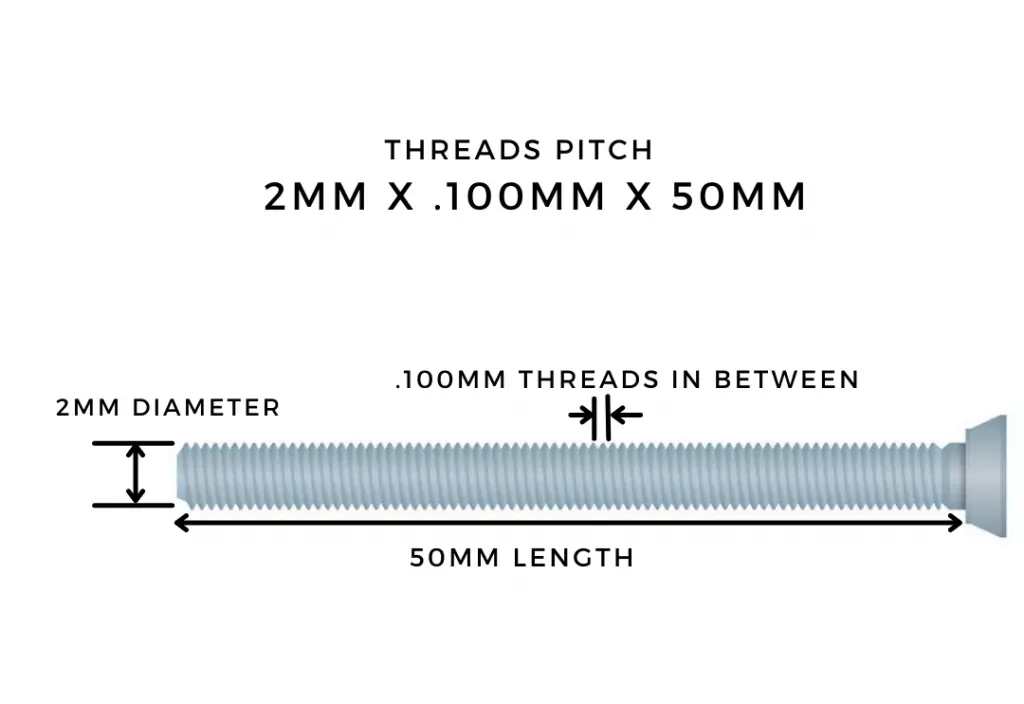

Now that you have the length and the diameter of the screw, you will have to find out the thread pitch of the screw. A thread pitch refers to the distance between the peaks of the thread in millimeters.

To get the thread pitch, you will need to measure the thread gaps within the screw thread. After counting each thread gap within the range of 1 mm, divide the number of thread counts by 1 mm, and you should get a thread pitch.

For example, if you have a screw with ten thread gaps in a 1 mm length, then your thread pitch will come out to be .100 inches. It means there is a space of .100 mm amidst each thread.

Keep in mind that the pitch should always come out to be less than 1 mm. The correct way to represent a screw thread size of the metric system is to write it as 2mm x .100 mm x 50 mm. The 2 mm is the diameter, .100 mm is the thread pitch, and 50 mm tells the length.

How to Measure Screws Using a Thread Gauge?

Thread gauges are another way to determine the dimensions, diameter, and pitch of a screw thread. A thread gauge, also known as a pitch or screw gauge, uses the trial-and-error method by first applying a known-sized component, then the unspecified component.

If these pieces fit well, and there is no resistance except for a little, consider both of them having similar sizes.

Although this method does seem to be a straightforward approach for measuring the screw thread size, it is still not recommended to entirely rely upon as it can produce corrupt results if carried out frequently.

It is because problems occur while depending on properly-sized fasteners, and unintended mixing of metric and imperial threads can confuse you while using this method.

Numerous types of thread gauges are available with different metric and imperial thread sizes. Ring gauges are a perfect example as these can easily find out the dimensions for screws, bolts, and other various threads. The video below explains using a ring gauge to identify the thread size.

Thread gauges come in ‘go’ and ‘no-go’ categories. It means that if a thread had adjusted itself in the ‘go’ gauge and isn’t in the ‘no-go’ gauge, then you can say that it is rightly determined.

You can check out one of my favorite thread gauges here.