Balsa wood is quite porous and very tricky to drill in. Last week, while trying to build a mini home model out of balsa for my kid, I struggled to make straight & clean holes. This pushed me to experiment with finding a solution to this problem, and I found some clean methods to do it right. Here’s how it’s done.

How to drill into Balsa wood? Use a well sharpen brass tube fitted in a drill bit and apply the right amount of pressure to avoid tear-out in the wood. You can also use a sharp spur drill bit at high speeds to avoid splintering. Using some glue with paper can also help in making clean holes.

It would be interesting to know that even the smallest of things like keeping a firm hold on the drill machine and using the right type of drill bit for the balsa wood are deciding factors that determine drilling accuracy.

Ways to drill through Balsa wood

Since balsa wood is not good for holding nails etc. and is therefore glued wherever needed. However, for making building models, small holes are drilled in some cases. A few methods to drill in balsa wood are given below:

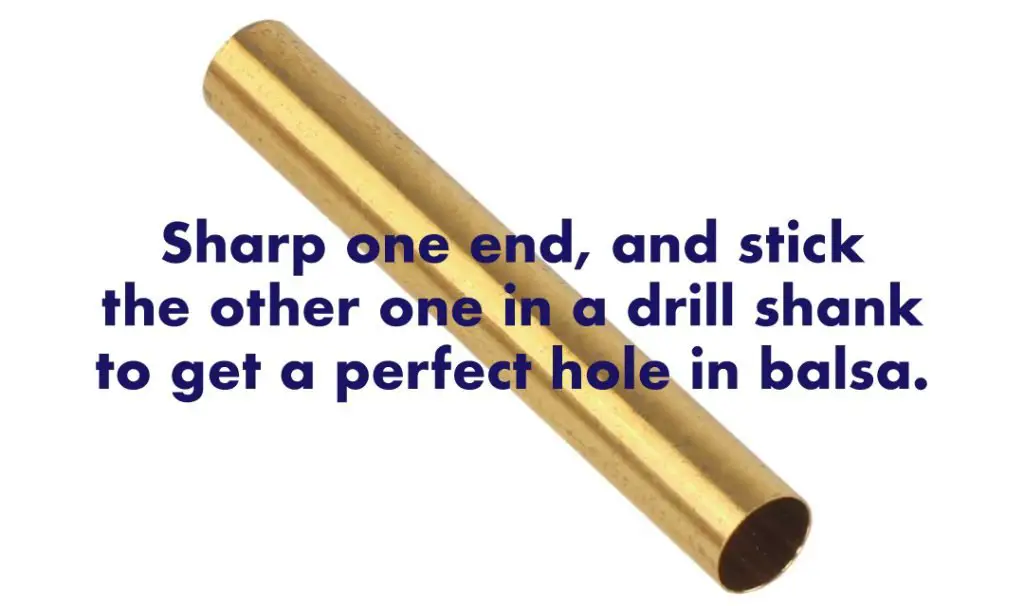

#1 Using brass tube to drill into balsa wood

The biggest issue with balsa wood is splintering and the wood getting crushed; the best method is to use a brass tube with the drill.

- The first step is to file the brass edge with a round tip filer to sharpen it.

- After this, the brass tube is mounted on the drill.

- Mark the point where you intend to drill and place it under the brass tube.

- Start the drill and gradually lower the drill machine to exert pressure to make a hole.

- The brass tube will drill out a cylindrical shape wood piece stuck inside.

- Remove the inner circular wood piece from the brass tube at the end.

#2 Drilling with drill bits

Different types of drill bits are used depending on the size and thickness of balsa wood. Some of the ways to drill balsa wood using a drill bit are discussed below:

Using spur wood drill bits

The main problem while drilling holes in balsa wood are its soft nature, which causes the wood to bend & press easily. Thus, the holes misalign from the marked point.

It can even break if more pressure is applied. Therefore, you can drill thick balsa wood planks with spur drill bits (learn more about drill bit types here). Keep the drill machine well aligned and start at a slow speed but ramping it up quickly. Let the drill bit finds its way inside rather than applying pressure.

This procedure might fail in drilling holes of larger diameters since that can crack the wood chunk. You can draw a circle and cut the balsa with a cutter for larger holes. For deeper holes, use a well-sharp saw drill bit at high speed.

In the hand drill machine, if drilling at an angle is required, the drill bit’s fast circular motion causes the drill bit to deviate from the point of drilling.

This problem can be tackled by first drilling vertically to make a mark on the wood. Once the wood is marked, then drill at the required angle.

Using hole-saw and forstner drill bits

So for drilling larger holes, you will have to use a hole-saw or Forstner drill bit. Here is how to do it.

- To make a mark on the balsa wood sheet, use a thin drill bit to drill through the wood.

- Now, use the smaller hole as a guide and drill the larger hole with a saw bit or Forstner bit. Keep the center guide on the small guide hole.

- Make sure the hole is drilled up to half of the total thickness of the sheet.

- Turn the balsa wood sheet over in such a way that the backside and front side are flipped. Repeat the drilling process in the same way, i.e., keeping the smaller hole at the center and drilling up to half of the total thickness.

- Make sure to move the drill machine slowly across sheet depth to avoid rough edges.

A hole with such way will avoid splintering and breaking the sheet. You will have a clean outcome.

#3 Avoiding splintering by using scrap wood platform

As mentioned earlier, larger holes might cause tearing and cracks in balsa wood while drilling. You can also avoid this by following this method:

- Place the balsa wood on a scrap wood piece. Make sure that the scrap wood is bigger than balsa wood.

- Hold the scrap wood and balsa wood firmly together. It is recommended either to clamp both the pieces or to utilize some alternate approach so that balsa wood does not move on the scrap wood platform while drilling.

- Align the drill machine with the marked point of the hole and exert pressure slowly on the sheet or chunk of balsa wood in such a way that the pressure distributes evenly while drilling.

- Wear a face mask and safety glasses during drilling so that wood dust might not irritate the eyes or nose. Wear clothing and gloves to avoid irritation on the skin.

- Move the drill bit or brass tube up to the depth of balsa wood. Go deep enough to drill a few MMs in the scrap wood.

#4 Gluing paper to avoid tear-out

You can also sea the balsa wood with highly effective glue initially to avoid tear-out while drilling. The glue hardens the surface of balsa wood, thus making the process of drilling neat and clean.

#5 Punching holes in balsa wood corks

In case you don’t have a drill, you can punch out a hole using a sharp brass tube. Be extra careful not to use this method on thicker sheets as the punch can press it all together.

Suppose the balsa wood is thick. Then rotate the tube with your hands to drill in. Balsa is soft so that you can have some success with this method.

How to drill multiple sheets of balsa wood

Tear-out mainly depends upon the thickness of balsa wood. The greater the thickness, the more is the chance of uneven pressure by brass tube or drill bits, and the greater is the chance of tear-out.

If you plan to drill multiple holes in a few sheets of balsa at once, you will have to hold them tight together. To do so, you can place some weight on both ends or use some rubber bands.

How to drill and cut plywood

Like balsa wood, plywood is also soft in nature and is often used with balsa to make structure models or RC planes.

It is recommended to drill through the front face to get clean holes without rough edges.

Drilling plywood sheets is a little tricky due to its construction. It is made by gluing multiple wood sheets together. So, splintering is very common when drilling holes.

You can avoid it by using a scrap board beneath or using a well-sharp auger drill bit. When making larger holes, select a hole saw with more cutting teeth.

Recommended Drill:

You can get a normal DIY or budget drill for this task from this list I have compiled. You don’t need to get an expensive drill for drilling into balsa wood.

Related questions

When to use a drill press over a hand drill?

The material being drill is too hard, or you have to drill many holes too precisely. For balsa, a drill press will be overkill.

Drill press also helps stop bit wondering.

How to cut balsa wood?

The best way to cut balsa wood is using a paper cutter. Do not try cutting it in a single go; give it multiple cuts for smooth output.

For larger wood planks, you can use a saw having multiple teeth.

What happens if the balsa wood is drilled too slowly?

Slow speed causes the drill machine to catch more wood grain which increases the chances of tear up. Therefore, drill at high speeds for better results.