If you drill veneer wood without proper knowledge, it can cost you the aesthetics of your furniture.

A veneer is a ply of expensive and exotic hardwood that usually covers the nonexpensive softwood sitting underneath.

Although Veneer is usually very resilient to stresses, it can still crack during drilling, which is quite absurd to repair.

Drilling veneer wood is a challenge in itself. It can crack, chip, or tear quite easily, but we can still prevent it by avoiding the traditional twist drill bits. Use Forstner bit, brad point drill bit, or German colt drill. Place a piece of MDF over the surface for support, clamp the wood, or use blue painter’s tape to keep the wood threads in place. Sharp drill bits have less tendency to split the wood. In addition to this, a low feed rate with high speed is also very effective.

Due to its cost-effectiveness and resilience, veneer wood furniture can outlast typical ones.

Although veneer wood has got a lot of pros, it also comes with its downsides. When drilling into veneer wood, it must be kept in mind that it can chip very easily.

I have some recommendations on avoiding it, which I learned through my personal experiences and experimentation.

Pros of using veneer wood

- Cost-effective

- Doesn’t Crack or Warp

- Humidity resistant

- Excellent for large surfaces

- Multiple options to choose from

Cons of using veneer wood

- Harder to repair

- Not capable of refinishing

- Not quite durable

- Not good for heavily used surfaces

Why does hole splintering happen in veneer wood?

Splitting, splintering or chipping refers to the fragmentation of wood. This is a serious concern when drilling into veneer wood. I have listed some of the causes below:

- Low-speed drilling

- Applying excessive pressure

- Using wrong drill bits

- Using blunt drill bits

- Drilling on the edge

How to drill Veneer Wood without hole splintering?

“Prevention is better than cure” also stands true for wood splitting. Once the veneer wood is shattered, it’s nearly impossible to repair. Therefore when drilling into veneer wood, caution must be exercised. Below I have compiled some points on how to prevent veneer wood.

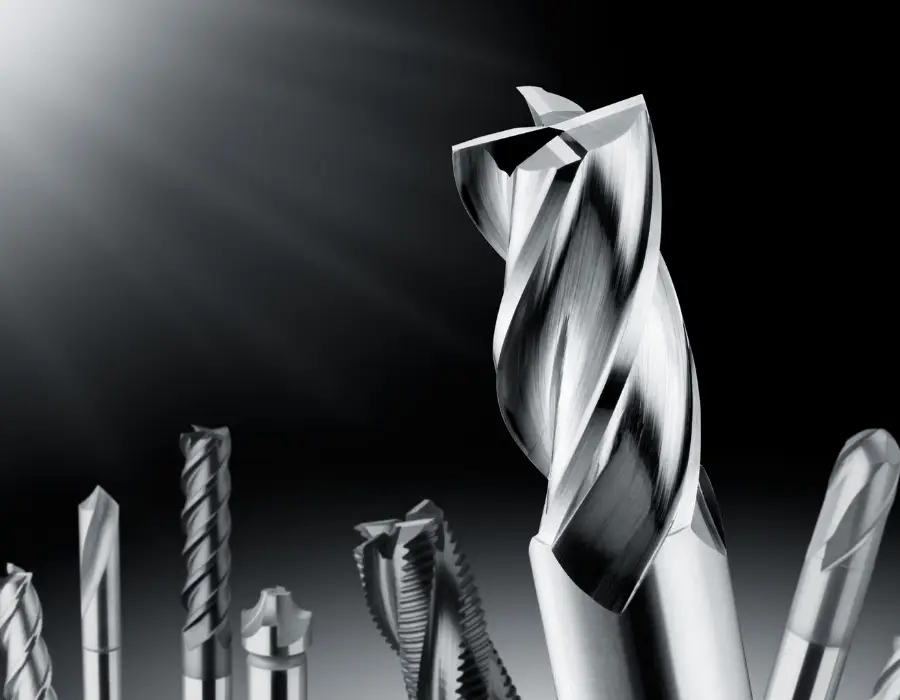

1. Use Appropriate Drill Bits to drill veneer wood

To drill veneer wood, you will need a good knowledge of selecting an appropriate drill bit. Therefore, I have discussed them in detail below.

Traditional Twist Drill Bits

Drill bits come in different sizes, shapes, geometry, and material. Although traditional twist drills can do the job, they tend to split the edges more often than the typical ones; this is due to poor hole axis maintenance, concurrently vibrating the bit.

Twist drill bits with a point angle of 118 degrees can do the job but are usually not recommended.

Forstner Drill Bits

Forstner bits are designed to work on wood, and the veneer is no exception. They are exact and cut a clean-edged hole, preventing splinter. Forstner bits come in different sizes; therefore, proper selection is important. Although they are expensive, they usually last longer than traditional ones.

Forstner drill bits work better with powerful drills. I have made a list of a wide variety of cordless tools you can select for drilling into veneer wood.

Brad Point Drill Bits

A Brad Point Drill bit (Learn more about them here on this site) has a pin in the center that prevents the bit from wandering around. This provides an excellently clean and precise hole. Moreover, the pin also helps to drill at an angle. Therefore I strongly recommend Brad-point bits for this purpose. Carbide-tipped Brad point drills are long-lasting and should always be considered.

2. Placing MDF Over the Surface

Placing a sacrificial piece of Medium Density Fiberboard on the top of veneer wood prevents tears while drilling. The fiberboard helps keep the wood layers in place. The size of MDF should be large.

3. Wood Clamp

It is ideal for drilling on edge. Place the clamp lateral to the hole point in a secure position. They come in many sizes and shapes. Always select the appropriate clamp for the job.

4. Blue Painters Tape

We are lucky enough to have painter’s tape available nowadays. Applying the tape on edge and opposite the drilling point prevents blowout wood splitting. Maskers tape can also do the job but is very difficult to remove after drilling into veneer wood.

5. Using Sharp Drill Bits for veneer wood

Please refrain from using blunt drill bits to drill veneer wood because they have the maximum tendency to split the wood. Sharp drill bits cut through the wood very easily and precisely. Drill bits should be sharpened by a professional.

6. High Speed, Low Pressure, and Low Feed Rate.

When drilling with high RPMs, there is the least tendency for a split to occur. Never apply excessive pressure when drilling through veneer wood because it will result in a blowout crack. Moreover feed rate should always be kept low. In short, when drilling into veneer wood, you must be patient.

Properties of Veneer Wood

Veneer wood, commonly referred to as the wood veneer, has some excellent properties that have endorsed its high demand.

A veneer is made out of hardwood, usually a Maple, Oak, or Cherry tree. This property gives it its resilience.

Whats the color & patterns of veneer wood?

Based on the species of donor tree, the color scheme can range from classic to modern. Ash, Alder, and Maple have light colors, while the Cherry and Beech’s tree has a reddish hue. Walnut and Oak have a brown color shade.

This is mainly based on the wood cutting technique. Horizontal cuts have a ring pattern to them, while longitudinal has parallel strips.

How resilient is a veneer wood?

Veneer wood is usually treated with nonpenetrant varnishes that provide it an excellent waterproofing and fire hazard safety. However, the varnish needs periodic reapplications.

Is veneer wood good for soundproofing?

A veneer is a poor choice for soundproofing. This is because the veneer is a skinny slice of wood that is usually not enough for good soundproofing.

Can you drill into the veneer?

Yes! You can drill into veneer very easily, but it has got its downside of chipping very easily. To prevent chipping, always use sharp drill bits that are intended to work on wood. Keep your drill speed fast and refrain from applying pressure. Ask for expert help when needed.

Can I drill into laminate?

Yes! You can pretty easily drill into the laminate, and this is no different than drilling into wood. Although due to its shiny surface drill usually slip and wanders around when drilling into the laminate. You can solve this problem by:

1. Denting the laminate with a sharp pin so that the drill bit is stable.

2. Apply adhesive tape, which will act as a stabilizer.

Can you use a Forstner bit in a drill?

Yes! Although you can use a Forstner bit in a handheld drill, it is actually intended for a drill press. During the drill, it tends to slip and wander away at the start of the procedure. When using a Forstner bit, use a clamp and sacrificial board to create a jig. The jig will prevent the drill from wandering around.