Nothing is more annoying than doing a ton of work on a piece of wood, and when making a hole, boom, and your workpiece is just splintered in half.

Luckily, to drill a clean hole in wood without splintering is simple and only requires being careful and adjusting your drilling techniques.

Do the following to bore a hole in wood without splintering the hole or workpiece

- Always use sharp and well-mainated drill bits

- Drill at higher speeds

- Avoid putting pressure on the drill and let the drill bit finds its way through the wood

- Use a sacrifical board under the workpiece

- Use a blue carpenters tape on both sides of the workpiece

- Drill from both ends for a clean hole in wood without splintering

Wood splintering is also known as Blowouts or Tearouts. The method you can use to avoid blowouts can be different and depends upon the use case & the wood type you are using.

The hole’s diameter also plays a vital role in deciding the method you can use to avoid splintering.

Steps to Drill a Hole in Wood Without Splintering

Following are a few methods that will help you make a clean and perfect hole. I am going to mention the most common and easiest ones first.

1. Drilling holes in wood – The correct techniques

Before we dig into specific tricks and picks, I am going to share a few things you should generally take care of when looking forward to solving the mystery of how to make a hole in wood. These precautions will also help you on how to keep wood from splitting when drilling.

- Always use sharp and well-maintained drill bits to get a clean hole.

- When boring holes in wood, it is always recommended to run the drill at full speed. Often slow speeds result in wood splintering; make sure you are using a powerful drill like this. An under-power drill is a reason for a splintered hole.

- Let the drill do its job and avoid putting pressure on the drill as that can cause a blowout, especially at the end when a thin layer of wood is remaining. Since wood fibers are in one direction, a small splinter can propagate in no time. It is better to hold the drilling firm not to push in when you reach the end of the hole.

- Maintain your drill properly so it can deliver its best speed and power. This also implies with fully charged batteries, so there is no drop in performance.

- Use the right type of drill bit for every job you are planning to do. Ensure that the drill bit you are using is recommended for the task you are about to perform. A little time spent in a quick R&D before making the hole will save you a lot to fix the hole.

Related Read: 09 Best Cordless Drills for home use

2. Use the correct drill bit to make holes in wood

Using the correct type of drill bits for wood is essential as a wrong one will increase the probability of a splintered hole. You can certainly use almost any drill bit to make a hole in wood due to the material’s soft nature; however, a clean hole without splintering will require you to use the expert’s and manufacturers’ recommended bits.

Below is a comprehensive table summing up the wood drill bit types and their usage.

| Bit Type | Description | Advantages | Limitations |

|---|---|---|---|

| Twist Bits | Most commonly available drill bits and used for metal, acrylic & wood. | Available in size as small as 1mm (3/64″) and go up to 13 mm (1/2″). Can drill in timber very easily. | These bits tend to wander, especially when drilling at an angle. This results in rough entry holes. |

| Brad Point Bits | Specifically, design for drilling in wood with a center tip and sharp spurs. | Very neat & accurate holes. Come in various sizes up to 13mm (1/2″) | It cannot be used to increase a diameter of an existing hole. Better use Twist Bits for that purpose. |

| Spade Bits | Great for high-Speed Drilling in wood. It comes with a center point for drilling straight. | Can drill larger holes up to 40 mm (1-1/2″) and comes in extra long length up to 400 mm (15 inches) | Good for speed working or construction sites. Not recommended for fine woodworking. These bits are not so accurate concerning the hole diameter. |

| Turbo Auger Bits | Great for faster and accurate wood drilling. Comes with Center Point and 2-4 Spurs | Very Accurate & Fast for timber. It works great for drilling a straight hole at an angle—diameter up to 30mm. | Requires a powerful drill for larger holes. |

| Forstner Bits | Specifically designed to drill clean holes with a flat bottom | Clean and Accurate Drill depth and diameter. Creates Flat Bottom—size up to 50 mm. | The drilling speed is a little lower and needs a powerful drill. |

| Hole Saws | It’s more like a saw in a circular shape and designed for larger diameter holes. | Very Neat hole and works great for sheets & boards. | Limited Depth and requires a powerful drill. |

| Pocket Hole Bits | Used with a jig to make pocket holes. | Specialized Shape for making a pocket for joints in woodworking | Useless without a Jig. |

| Multi-Angle Bits | Designed to drill curved holes with changing angles. | Clean and Fast holes at multi-angle. | Making a straight hole is a little difficult. |

| Counter Sink Bits | Designed for Counter Sink Screws to get a flashed surface. | Neat & clean holes for the screws to sit in. | Small Depth. |

Related Read: 25 Drill Bit Types [Explained]

3. Drill With a Sacrificial Board to Avoid Blow Outs

To avoid Blow Outs or wood splintering while boring a hole, use another sacrificial board beneath the actual workpiece. The wood fibers tend to blow out when the drill approaches the end. The sacrificial board helps stop it by practically making the workpiece deeper.

Once you’re done with the hole, remove the sacrificial board, and you have a clean cut-out. Using a sacrificial board might not be possible in every scenario, so you may have to use other methods to avoid splintering.

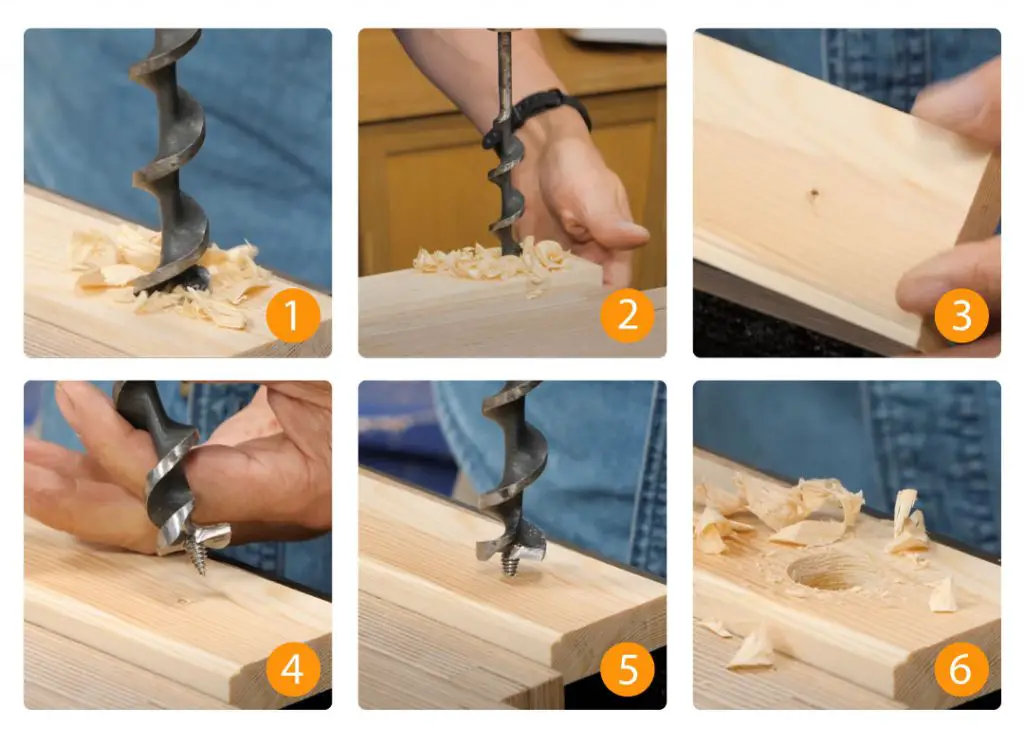

4. Drill From Both Sides to Avoid a Hole Tearout

This is an excellent technique and is widely used to avoid wood splintering while making a hole. You can achieve this with multiple methods. One is using an auger bit with a pointed center tip. Start drilling a hole and reduce your speed at the end. Once the tip of the drill bit is visible on the other side, stop the drilling. Then drill from the other side at the same spot marked by the bit tip.

The other method is making a pilot hole with a thinner drill bit. Then use an auger drill bit to make a hole from one side to the center. Then drill from the other side to complete the hole.

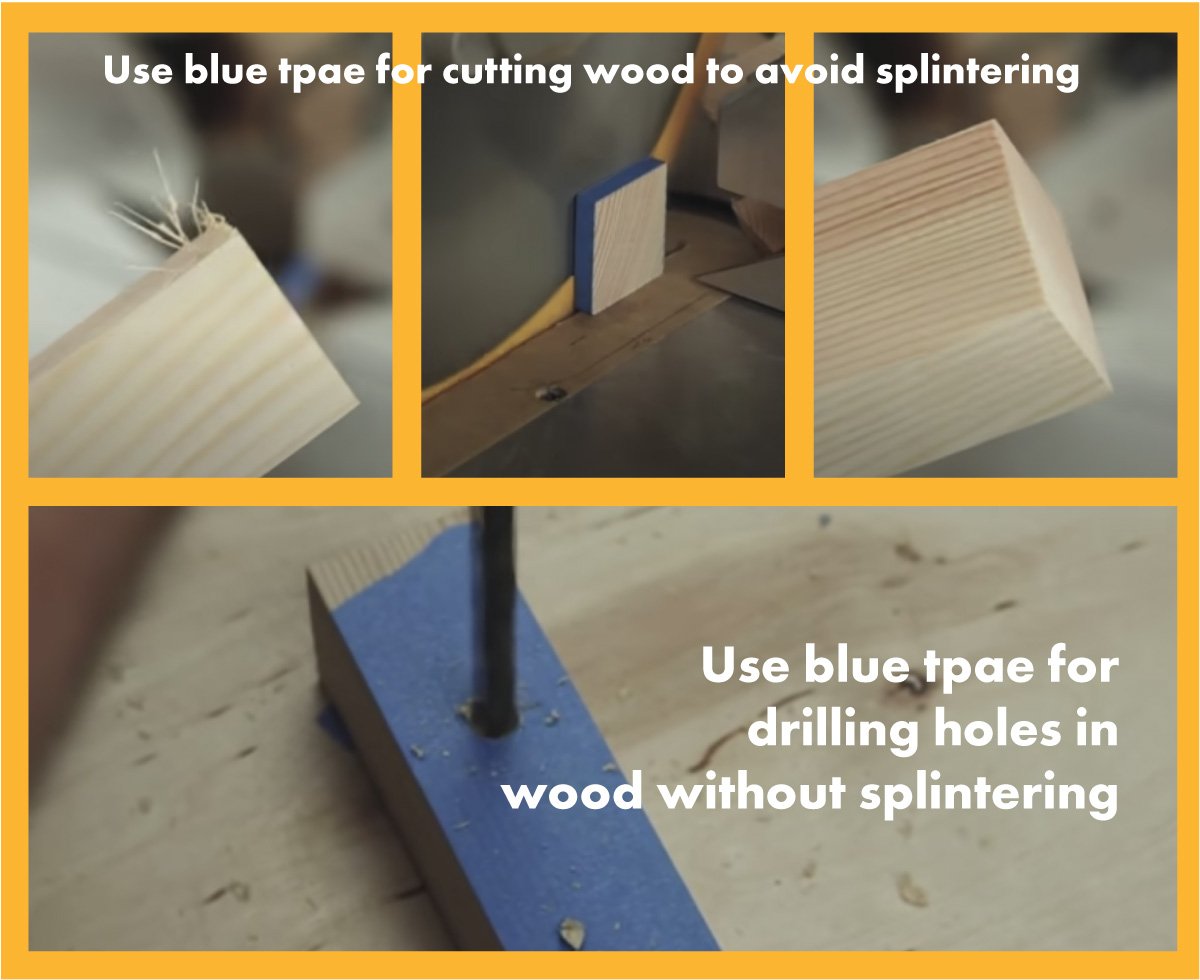

5. Using a carpenter tape on both sides

A blue carpenter’s tape can also help in drilling holes in wood without splintering. Paste the carpenter’s blue tape on both ends of the wood. Mark the spot you plan to drill. Use a sharp drill bit & drill at high speed.

The tape at both ends will keep the wood fibers intact from splintering and you get a clean hole. Carpenter tape is easy to pull off later as it is less gluey.

How to fix and smooth splintered wood holes?

Fixing a splintered or tear-out hole is quite difficult. The reason behind this is that the splintered piece is quite small and thin. Still, you can use a few different methods to fix a hole to make it cleaner and smooth.

You can repair a splintered hole by carefully removing the broken fibers at the tip of the hole so that the splintered fibers can sit in properly. Then apply wood glue thoroughly and press the outer fibers for a few hours to let it set. Once done, use a sharp cutter to make the hole clean. You can also use putty to fill in the splintered surface.

Which types of woods are prone to wood splintering?

Normal splintering and hole splintering are different, however, woods prone to normal splintering will have a high tendency to a blowout. Woods like cumaru, mahogany, wenge, maple, hickory, aspen, redwood & western red cedar are prone to splintering.

As discussed, it is more about your skillset and drilling technique. A proper approach can save your project from a catastrophe.

How to drill a large hole in wood?

For drilling a large hole in wood, you will need saw blade drill bits which are specifically designed to drill large holes in wood.

Just make sure to follow these steps when drilling a large hole in wood:

- Use a powerful drill machine as saw blades to avoid stucking your saw drill inside the workpiece.

- Use the appropriate size drill bit from the most trusted sellers.

- Use a drill bit with a center pilot hole drill bit so the drill stays firm in a single place and you get a clean hole

- Apply carpenters tape on the wood piece to get a clean hole

- Use a scarifical board under the workpiece if possible

- Drill at high speed

- Don’t apply too much pressure, specially at the end of hole

- Drill from both ends if possible

Below are the best and time-tested hole drill bits you can get for your woodworking project. These recommended Hole Saw Drill bits will cover most of the sizes including 2 inch, 4 inch, 6 inch of a hole.

1. 13Pcs Saw Blades – Ideal for Soft Wood, Plywood, Drywall, PVC by HYCHIKA

2. Laiwei Bi-Metal Hole Saw Kit, 7 Pcs Hole Saw Drill Bits, for Wood, Plastic, Drywall, Soft Metal

3. 10-Piece Hole Saw Kit for Wood – Kit For Wood, PVC, Plastic, Drywall

How to drill 1 inch hole in wood?

When drilling a 1-inch hole in wood, you will need to make sure your drill bit is powerful enough to go through the wood. If you are drilling into hardwoods like maple, oak, or walnut, then make sure you are using a professional drill with high-quality drill bits to avoid a stuck drill bit in wood.

You can use the following types of drill bits to drill a 1-inch hole in wood:

- Spade Drill bit – If you need to drill at high speed and quality of hole is not important. (Link to a TRI FLUET 1-inch spade drill bit on Amazon)

- Turbo Auger Drill Bit – For high speed, clean and acurate hole. (Link to a 1-inch Turbo Auger Drill Bit on Amazon)

- Forstner Drill Bit – For accurate clean holes, small depth. (Link to a 1-Inch Forstner Drill Bit on Amazon)

- Hole-Saw (I won’t recommend using this for such a small hole)

When drilling a 1-inch hole, follow all instructions explained above for a clean hole.

How to drill a 2 inch hole in wood

When drilling a 2 inch hole in wood, again make sure your drill bit is powerful enough to go through the wood.

You can use the following types of drill bits to drill a 2 inch hole in wood:

- Forstner Drill Bit – For accurate clean holes, small depth. (Link to a 2-Inch Forstner Drill Bit on Amazon)

- Hole-Saw – For larger holes like 2-inch, you will have to use a hole saw drll bit. (Link to a 2-inch hole saw bit on Amazon)

When drilling a 2-inch hole, follow all instructions explained above for a clean hole.

Related Questions

How do you drill smooth holes in wood?

Using a Forstner Drill or Turbo Auger Bits will give you a smooth neat & clean hole. Drill from both sides to avoid any splintering.

Do you need to drill a hole before screwing into the wood?

Yes, you should drill a pilot hole before screwing in wood to avoid splitting and cracking. This hole is known as a pilot hole.

Does a drill bit make a round hole?

Yes, and always. A drill bit is supposed to rotate, creating a circular motion, which then drills a circular hole. If you need a hole other than circular, you will have to use a chisel or saw.