If you are a craftsperson, you would probably know the importance of different types of drill bits and how much of a time-saver they can turn out to be.

You could be working on a project, and realizing that you do not have the right drill bit, can indeed ruin the work-day for you.

However, it is equally important to know the drill bits’ correct usage to avoid messing up. For this reason, I have come up with an ultimate guide to 25 different types of drill bits and their uses to save you from much hard work.

There are many types of drill bits, for instance, twist bits, installer bits, spade bits, and high-speed drills. These bits have their respective purposes of serving you when you need to use them.

Materials of Drill Bits

The material of a drill bit plays a major role in making sure that you are working with as much efficiency as possible.

You would come across many different drill bits with other purposes, so there is no hindrance while completing a task. The suitable material will save a lot of your time, energy, and money for sure!

Here are some materials that you should know before purchasing a suitable drill bit;

Carbon Steel

Suppose you want low or no heat generated while drilling; carbon steel might be a good choice for you.

The two kinds of carbon steel, both high and low, can work differently. You can use low-carbon steel to cut or drill into softwood and plastics. These are relatively cheaper but require good maintenance.

At the same time, high carbon steel will be best for cutting into woods and metals. These have better reliability and require little maintenance. They also come with finer durability than low carbon and are more favored.

High Speed Steel

High-speed steel is well known for drilling into hard surfaces because of its wear resistance and increased hardness.

It is specifically designed to handle the rising temperature and allow the drilling process to occur at higher temperatures. You can use high-speed steel for wood, iron, and other metals like brass and aluminum.

Cobalt

Cobalt drill bits are specially designed to drill hard and stiff materials like stainless steel and other rigid substances such as cast iron or titanium. It can resist a tremendous amount of heat which is why it stands perfect on any surface of any resistance.

Solid Carbide

Solid carbide drill bits will prove a perfect fit for stiff materials. These drill bits are entirely made from solid carbide, which is the crucial point here.

Carbide-Tipped

These drill bits are somewhat similar to the solid carbide bits as they are also made out of carbide.

The only difference is that these are not wholly produced by carbide except for their tips. It is because carbide is one of the most rigid materials, and it costs just as much.

So, to reduce the market price, the bits are only tipped with carbide.

The carbide-tipped drill bits can help drill to tile, masonry, and other hardened materials.

Coatings of Drill Bits

After discussing the materials, now comes the coatings of the drill bits, which is another way of distinguishing between certain kinds of drill bits.

TiN (Titanium Nitride)

TiN provides a variety of speed ranges to work with. These bits will stay flexible for more time than the other bits because of their high durability.

It is also essential to provide a heat build-up solution and let little friction occur.

Black Oxide

Black oxide coating will minimize the friction while cutting, which will prevent the extreme heat up in the drill bit. Ultimately, the flow of material will also improve.

Diamond

Diamond bits coating will prove a fantastic choice if you drill on hard materials such as glass, tile, or metals. Although they are exceptional performers, you will still have to think twice before purchasing as these cost a lot.

25 Different Types of Drill Bits and Their Uses

1. Twist Drill Bits

Twist bits are one of the most used drill bits out there as anyone can utilize them, be it a regular craftsperson or a professional.

These bits can do a great job drilling through wood, plastic, steel, and even concrete. They are mostly known to be great performers when cutting metal.

Check out one of my favorites here.

2. Counterbore Drill Bits

Counterbore drill bits are used for enlarging an already existing hole to make the screw stand firmly at its position.

The counterbore drills a hole of the same length as the screw upto the screw head.

3. Countersink Drill Bits

A countersink drill bit is also commonly called a screw pilot bit. It is used for drilling into the wood and can also drill pilot, countersink, and counterbore holes simultaneously.

4. Flat Bottom Boring Bits

Flat boring bits will be a lifesaver when you want holes with flat bottoms. They will drill holes of the desired type and shear material as you are drilling through it, making it possible to have a smoothly finished hole.

These bits can also be used for counterboring holes, producing half and intersecting holes as well as holes at an angle.

5. High-Speed Dill Bits

High-speed bits are formed with vanadium and tungsten elements which is the main reason behind their exceptional strength. These perform effectively when used for steel drilling or other general purposes.

You probably know these as twist drill bits as this is what they are commonly known as, due to their cylindrical shank and the fact that you can use them for almost anything.

6. Masonry Bits

Masonry bits are a great option if you want to drill into tough surfaces like concrete, mortar, bricks, and stone.

Their toughness is due to the Tungsten carbide tipped at the top of the drill bit. It becomes easier to identify these bis as their tip is wider than the shank.

However, as much as they are hard, they wear out quickly. For this reason, you will need to change the bits more often.

You can drill with a masonry bit a maximum of 400 mm as their sizes range from 4 to 16 mm.

One drawback while working with one of these bits is that they tend to heat up quickly. It happens when the tungsten coating on the tip melts, generating enough heat.

To solve this problem, it’s essential to keep cold water nearby and dip the drill now and then before drilling.

7. Auger Bits

Auger bits are known to be smooth and require lesser pressure than most of the drill bits; because of a screw-thread tip, only minimal effort is needed to work with it.

You can easily use it on thick and dry wood to drill comparatively large holes. It consists of a hexagonal shank that further strengthens the grip.

8. Rivet Bits

Professionals use the rivet bits mainly because of their unique ability to drill short and precise rivets into thin sheets of metal plates.

9. Spade Bits

As the name suggests, spade bits are shaped like a spade to cut through holes into softwood. Primarily, these bits are used for boring holes in running cables.

10. Step Bits

Step bits are primarily shaped as a series of pyramid steps used to drill holes of differing thicknesses across the metal sheets. The step bits are the go-to bits because of their flexibility.

11. Brad Point Bits

These bits come with rubber stoppers to ensure a desired depth of holes into the surface. The brad point bits will also create precise and cleaner holes compared to other drill bits.

12. Installer Bits

The installer bits come with a different purpose for installing wirings for security and entertainment. They are also uniquely shaped as they have a tip.

13. Bullet Point Bits

For cleaner holes, go for the bullet point bits, as you can use them for plastic, wood, and metal.

14. Hole Saw

If you are going to create a wiring pass-through or put up door hardware, then a hole saw would be a good choice for starting your project. The hole saw will form a waste plug which a saw cylinder will then push out.

15. Self-Feed Bits

Self-feed bits comprise a screw at the tip that helps position the bit accurately and produces a precisely clean result.

However, while working with these bits, you will have to stop at regular intervals in order to wipe the dust away,

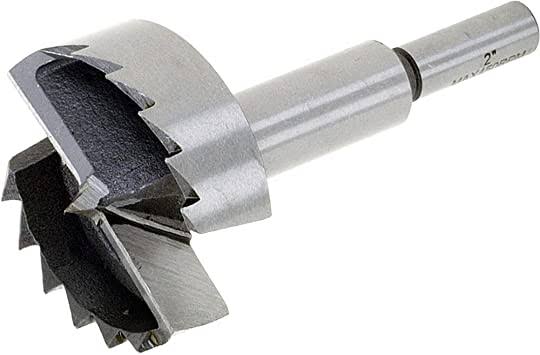

16. Forstner Bits

For smooth, clean, and accurate holes in wood, go for the Forstner bits, as these also come with a pointed tip that will let you control the positions.

17. Plug Cutter

A plug cutter is used explicitly for drilling into wooden surfaces and when you want to cut out a plug or make a hole in any wooden material.

18. Tile Bits

These bits are tipped with a carbide that ensures crack-free drilling into the tiles.

However, before purchasing these bits keep in mind that each tile bit works for different tiles, so make sure to check the packaging beforehand.

19. Hammer Bits

For an accurate and precise hole in a concrete slab, hammer bits will prove out to be essential drill bits, along with finding out the humidity level in that material.

20. Annular Bits

Annular bits will not only drill holes into distinct materials, but these bits will also let you extract the core.

21. Glass and Tile Bits

Glass and tile bits will work perfectly with any material, be it tile, glass, marble, or brick. In addition to that, they can also bear high temperatures as well.

22. Adjustable Wood Bits

These bits will be helpful when you need different sizes of holes with varying diameters, as these allow you to adjust themselves accordingly. This way, the need to get separate bits is minimized.

23. Bits for Metal

Bits for metal might seem a bit expensive to you as they have an excellent quality of cutting steel. You can drill into metal using bits for metal by following these 15 steps to drill into metal.

24. Rip Saw Blade

A rip saw is an essential blade that manually cuts wood in the grain direction speedily. It does so without even shredding or cracking.

25. Self-Centering Bits

These bits consist of a tip that will stay in the countersunk hole, placing itself along the center.

After pressurizing a bit, the bits will make their way into the material. The self-centering bits are used for creating hinges in wood and other similar materials.

Conclusion

Now that all of the bits are explained with their uses, you can easily choose which one to go for to complete your project.

Remember that making the right choice will save a lot of hard work. Once you buy one of these bits, it’s important to keep maintaining these drill bits in order to prevent them from wearing out.

Here are some additional tips for doing so;

- Make sure you use the correct speed for different materials. Hard surfacesneed a slow speed, whereas soft surfaces will require a faster speed.

- Like speed, maintaining pressure is equally important. Too much pressure might deflect the bit, and too little pressure will cause no difference in the material.

- To avoid rusting, keep the drill bits in a dry place.

- Always have a tighter grip when working with bigger bits as these carry significant force.

- Always keep the bit in the center.

- Avoid using the drill in the reverse mode, this will cause overheating.

- It is essential to keep cold water near you while using the bits.

- Frequent cleaning will make sure that your bits are free from any debris build-up.