A DIY enthusiast usually has multiple types of drill bits that keep on piling up as the need for drilling into different materials arises. The cutting angle of the drill bit is designed based on the sturdiness of the material being drilled.

The standard cutting angle is kept at 118 degrees and is usually for drilling into soft materials, whereas the 135-degree cutting angle is for drilling into harder materials like stainless steel.

What is a Split Point Drill Bit? A split point drill bit is a self-centering speed bit with a cutting angle of 135 degrees. It is specifically designed to drill into metal and other hard materials without wandering around on the surface.

Split point drill bit also reduces the amount of pressure needed to drill because they have two extra cutting edges at the chisel edge. In addition, the 3 grooves on the shaft of the split point bit allow an easy escape of debris, eliminating the bit snags.

The point configuration on different types of bits is specifically designed to suit the materials that are being drilled. This divides the bit into different types as Standard, Split, Screw, and Plexi point drill bits. I have researched and experimented with various configurations. In the article below, I will explain the Split point drill bit in detail.

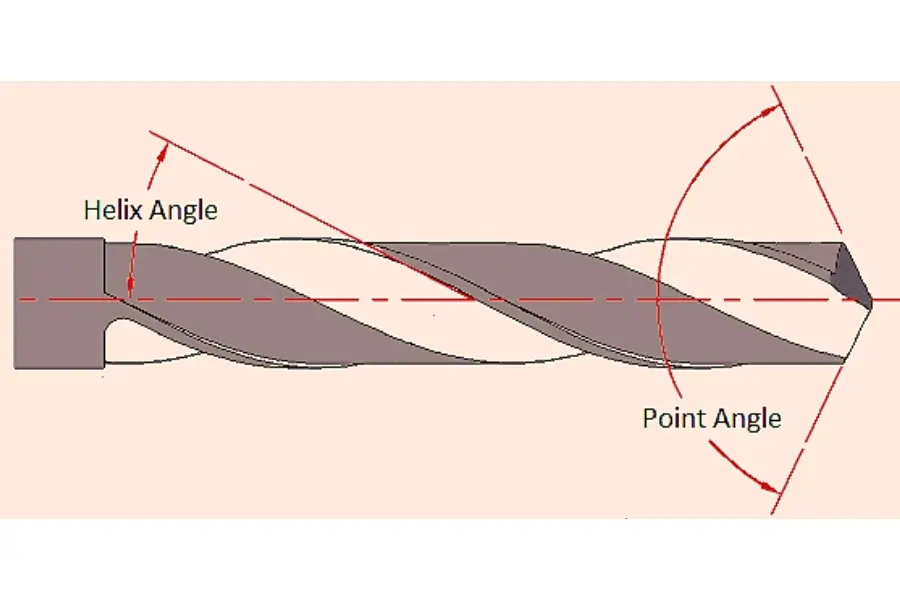

Cutting Angle of a Drill Bit

The cutting angle, also known as the point angle (Additional resource to learn more, click here), is the angle between the two lips/faces/edges of a drill bit. It must be projected on a plane parallel to the axis. Both the edges are sharpened at the same angle to the center, so the cutting angle is actually the sum of the angle of both faces.

The angle determines the capability and efficiency of a drill bit to drill into different materials. The larger the angle, the higher the capability of the bit to drill into harder materials. The standard bits have a cutting angle of 118 degrees.

Best Split Point Drill Bits

These are the few best split-point drill bits you can buy. These sets have a wide variety of sizes which will work out in most cases.

- Norseman Drill Bits 44170 Ultra Dex Type 240-UB 135 Degree Split Point

- Champion Cutting Tool Brute Platinum 29 Piece

- Viking Drill and Tool 44150 SP-29 Type 240-UB 135 Degree Split Point

Features of a Split Point Drill Bit

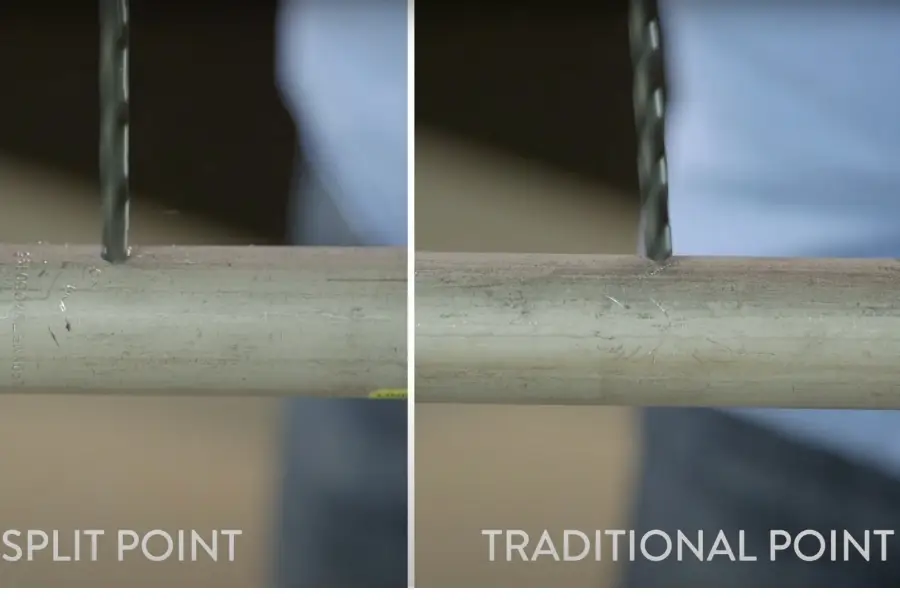

Apart from the standard point drill bit which has a smooth tip, split point drill bits have two extra edges. When you are drilling into any material the standard bits have a tendency to walk away so you need to have a center punch to get started.

The beauty of the split point drill bit is that it has greater stability because of the extra edges, which eliminates drill walking. I have numbered the features of split point drill bit below,

- The split point drill bit has a grooved tip rather than a smooth one. This is the main reason for its name. In addition, the split-tip provides extra support to the bit, eliminating possible slips.

- It has a cutting angle of 135 degrees. This makes the split point drill bit efficient enough to drill into harder materials like steel.

- A good quality split point drill bit’s shaft usually has three groves; these groves help push away the hole’s debris. This helps to get a cleaner hole.

- The bits are designed to eliminate snag; it drills a finer hole.

Uses of Split Point Drill Bit

The split point drill bit has multiple applications. They are superior to the standard drill bits but have one problem: their non-sturdiness, i.e., they are more prone to damage than standard drill bits. I have briefly mentioned the uses below,

- A cutting angle of 135 degrees enables them to drill into stainless steel.

- They are more useful for drilling into slippery surfaces like metal pipes.

- Split point drill bits are used to avoid a center punch on the surface, like drilling into expensive wood.

- Split point bits are preferred to be used on cordless drills because of better stability.

- When a precise, clear hole is required.

- They can also be used to drill into hardwood.

Identifying Split Point Drill Bit

When walking into your local hardware store, you won’t find a specific designation that states that the bit is a split point; rather, you have to identify it with your own expertise.

You can easily identify the bit by looking closely at the image on the packing. If the cover is transparent, then you have to look at the bit point. A split point drill bit is cut at the tip, whereas the standard will be smooth.

Can you sharpen split point drill bits?

No! You can not sharpen split point drill bits because the edges are prone to breakage when you try to sharpen them with a diamond spin wheel. It is advised to buy a new set of split point drill bits when they are dull.

What is better 118 degrees or 135-degree drill bits?

118-degree drill bit is better for drilling into soft materials like wood, plastic, and aluminum whereas 135 degree drill bit is better to drill into hard materials like copper and stainless steel. This is because 118 degree has a small chisel and a sharp pointed tip where as 135 degree bit has a flatter edge and a larger chisel.

Which is harder carbide or cobalt?

Carbide is the hardest, sturdiest, and brittle drill bit metal currently available. In comparison, cobalt is an upgraded version of HSS and contains 5-8% cobalt in the mixture.